Contract Manufacturer for Cable and Wire Harness, Assembly Services and more.

Think of us as your one-stop source for custom manufacturing: Electromechanical Assemblies, Control Panel Assemblies, Wire and Cable Harnesses, Repair and Refurbishment Services, plus complete Engineering and Product Design.

We support your needs for manufacturing, product design, and prototyping. Our staff engineers and team members stand ready to become your essential manufacturing partners.

OUR SERVICES

Electromechanical Assembly

Heltronics has a well-equipped assembly department to fit all the electro-mechanical assembly needs.

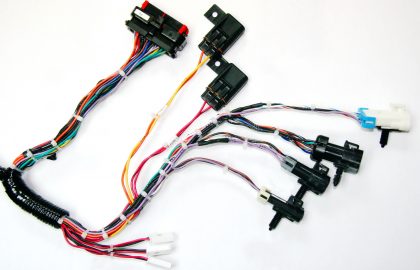

Cable and Wire Harness

We build custom cable and wire harnesses to your specifications–Automotive Cable, Communication Cable, Power Cable, etc.

Control Panel and Cabinet Assembly

We have a reliable, quality-assured process for building your control systems.

Rework and Upgrade

Rework and Upgrade of customer products includes testing and calibration to customer specifications.

Electronics Assembly

PCB assembly, such as throughole and SMT for short and medium runs.

Product Design & Engineering

From prototype to finished design, we support your new ideas.

We are contract manufacturer that over service in a wide variety of areas from electro-mechanical assembly, rework and refurbishments as well cable and wire harnesses.

We succeed when you succeed. Heltronics is committed to customer service and support and we have a driving passion for what we do. Never compromise on quality, do it right the first time, and make our customer’s production goals our own.

We believe in supporting manufacturers locally as well as the rest of the United States. This includes working with overseas partners to offer the most cost efficient and highest quality product to our customers.